Оборудование для розлива пива в бутылки является основой современного пивоваренного производства, обеспечивая точность, качество и эффективность упаковки каждой бутылки пива. От небольших ремесленных пивоварен до крупных производственных предприятий - эти машины играют жизненно важную роль в сохранении вкуса, газированности и свежести пива, удовлетворяя при этом запросы потребителей. Благодаря технологическому прогрессу пивоваренные заводы теперь имеют доступ к широкому спектру оборудования для розлива, отвечающего их специфическим потребностям, будь то мелкосерийное производство или высокоскоростные линии розлива. В этой статье рассматриваются основные компоненты, процессы и инновации, формирующие индустрию розлива пива, и предлагается информация о том, как пивоваренные компании могут оптимизировать свою деятельность и оставаться впереди на конкурентном рынке.

Оглавление

ToggleВведение в оборудование для розлива пива в бутылки

Обзор розлива пива в бутылки

Розлив пива в бутылки - важнейший этап процесса пивоварения, обеспечивающий безопасное и эффективное перемещение продукта из резервуаров в бутылки для распространения. Этот процесс не только сохраняет качество и газированность пива, но и обеспечивает постоянство состава каждой бутылки. Современный разливочные машины рационализировать эту операцию, сократить ручной труд и увеличить скорость производства.

Эти машины предназначены для работы с бутылками различных размеров и форм, что делает их универсальными для пивоваренных заводов любого масштаба. От небольших ремесленных пивоварен до крупных предприятий - оборудование для розлива в бутылки играет важную роль в поддержании эффективности и удовлетворении потребительского спроса.

Значение в пивоваренной промышленности

Машины для розлива в бутылки необходимы для сохранения целостности и качества пива во время упаковки. Они минимизируют воздействие кислорода, который может ухудшить вкус и свежесть, гарантируя, что пиво дойдет до потребителя в наилучшем состоянии. Кроме того, автоматизированные системы снижают риск загрязнения, повышая безопасность продукции.

Для пивоваренных заводов эти машины также повышают эффективность производства, ускоряя процесс розлива и сокращая количество отходов. Это позволяет пивоварам выполнять производственные задачи, сохраняя неизменное качество, что очень важно для укрепления репутации бренда и лояльности клиентов.

Типы оборудования для розлива пива

- Гравитационные наполнители: Эти машины наполняют бутылки под действием силы тяжести, что делает их идеальными для негазированного или слабогазированного пива. Они просты в эксплуатации и экономичны, что делает их популярными среди небольших пивоварен.

- Наполнители противодавления: Предназначенные для газированных напитков, эти машины поддерживают давление внутри бутылки во время розлива, чтобы сохранить газированность. Они широко используются на средних и крупных пивоваренных заводах благодаря своей точности и эффективности.

- Вакуумные наполнители: Эти системы используют вакуум для втягивания пива в бутылку, уменьшая воздействие кислорода и обеспечивая более длительный срок хранения. Они особенно полезны для высококачественного или специального пива.

- Роторные наполнители: Высокоскоростные роторные машины идеально подходят для крупномасштабных операций. Они могут одновременно наполнять несколько бутылок, значительно увеличивая производительность при сохранении точности.

- Ручные и полуавтоматические наполнители: Они подходят для небольших или начинающих пивоваренных заводов. Хотя они медленнее автоматизированных систем, они обеспечивают больший контроль и более доступны для ограниченных партий продукции.

Каждый тип оборудования для розлива пива служит определенной цели, что позволяет пивоварням выбрать оптимальный вариант в зависимости от производственных потребностей, бюджета и сорта пива.

Понимание процесса заполнения

Этапы процесса розлива пива

Процесс розлива пива включает в себя несколько ключевых этапов, обеспечивающих эффективную упаковку и сохранение качества продукта. Каждый этап направлен на минимизацию отходов, сохранение карбонизации и предотвращение загрязнения.

- Подготовка бутылки: Бутылки сначала очищаются и дезинфицируются, чтобы удалить любой мусор или бактерии. Этот шаг имеет решающее значение для сохранения безопасности продукта и продления срока годности.

- Продувка перед заполнением: Многие системы используют CO2 для очистки бутылок от кислорода перед розливом. Это уменьшает окисление, которое может негативно сказаться на вкусе и свежести пива.

- Наполнение: Пиво переливается из резервуаров в бутылки. В зависимости от оборудования это может происходить с использованием гравитационных, противодавленческих или вакуумных систем для обеспечения точности и минимизации пены.

- Укупорка: После наполнения бутылки сразу же укупориваются крышками, чтобы зафиксировать газировку и предотвратить загрязнение. Этот этап часто автоматизируется для обеспечения скорости и последовательности.

- Инспекция и маркировка: Наполненные бутылки проверяются на качество, обеспечивается надлежащий уровень наполнения и надежность укупорки. Затем они маркируются и подготавливаются к распространению.

Роль карбонизации в наполнении

Карбонизация играет важнейшую роль в процессе розлива пива, поскольку она напрямую влияет на его вкус, текстуру и общее качество. Поддержание надлежащего уровня карбонизации в процессе розлива очень важно для получения стабильного продукта.

Системы розлива под противодавлением обычно используются для газированных сортов пива. Эти машины поддерживают одинаковое давление внутри бутылки и резервуара, предотвращая чрезмерное пенообразование и потерю газированности. Это гарантирует, что пиво сохранит свой вкус и аромат, когда попадет к потребителю.

Кроме того, контроль карбонизации в процессе розлива помогает сократить количество отходов, поскольку чрезмерное вспенивание может привести к потере продукта и неравномерному наполнению. Правильно откалиброванное оборудование - ключ к эффективному управлению этим аспектом.

Сложности при розливе пива

Несмотря на развитие технологий, розлив пива в бутылки сопряжен с рядом трудностей, которые приходится решать пивоваренным компаниям:

- Проблемы с пенообразованием: Чрезмерное вспенивание при наполнении может привести к неравномерному наполнению, потере продукта и задержкам в производстве. Часто причиной этого являются неправильные настройки давления или перепады температуры.

- Воздействие кислорода: Кислород может ухудшить вкус пива и сократить срок его хранения. Обеспечение надлежащей продувки бутылок и использование герметичных укупорок - важнейшие условия минимизации воздействия кислорода.

- Техническое обслуживание оборудования: Регулярная очистка и техническое обслуживание разливочных машин необходимы для предотвращения загрязнения и обеспечения стабильной работы. Пренебрежение этим может привести к дорогостоящим простоям и проблемам с качеством.

- Изменчивость бутылок: Различия в размере, форме или качестве бутылок могут повлиять на процесс розлива, что приведет к неэффективности или сбоям в работе оборудования. Стандартизация спецификаций бутылок может помочь смягчить эту проблему.

- Масштабируемость: Для растущих пивоваренных заводов масштабирование производства может оказаться непростой задачей. Переход на более совершенные системы розлива требует значительных инвестиций и тщательного планирования, чтобы избежать сбоев в работе.

Понимая эти проблемы и внедряя передовые методы, пивоваренные компании могут оптимизировать процесс розлива пива и поставлять высококачественный продукт своим клиентам.

Типы машин для розлива пива

1. Автоматические машины для розлива в бутылки

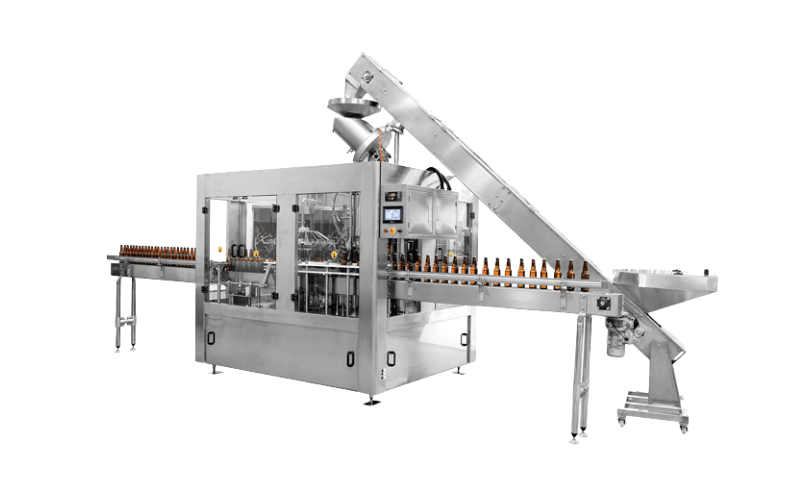

Автоматические машины для розлива в бутылки предназначены для оптимизации процесса упаковки пива, что делает их идеальным решением для средних и крупных пивоваренных заводов. Эти машины выполняют все операции - от очистки и наполнения бутылок до укупорки и этикетирования, значительно сокращая ручной труд.

Одно из их ключевых преимуществ - скорость. Автоматические системы могут разливать сотни и даже тысячи бутылок в час, обеспечивая пивоварням высокие производственные показатели. Они также обеспечивают точность, поддерживая постоянный уровень наполнения и минимизируя количество отходов. Многие модели оснащены такими передовыми функциями, как продувка CO2 для уменьшения воздействия кислорода, что позволяет сохранить свежесть и аромат пива.

Эти машины хорошо настраиваются, позволяя пивоварням регулировать настройки для бутылок разного размера и уровня газирования. Хотя первоначальные инвестиции могут быть высокими, долгосрочная эффективность и экономия труда делают их достойным выбором для растущих предприятий.

2. Полуавтоматические фасовочные машины

Полуавтоматические разливочные машины - отличный вариант для малых и средних пивоваренных заводов, которым нужен баланс между автоматизацией и ручным управлением. Эти машины требуют некоторого участия оператора, например, для позиционирования бутылок или инициирования процесса розлива, но при этом автоматизируют такие ключевые этапы, как розлив и укупорка.

Главное преимущество полуавтоматических машин - их доступность. Они стоят дешевле, чем полностью автоматизированные системы, что делает их доступными для стартапов и пивоваренных заводов с ограниченным бюджетом. Кроме того, они обеспечивают гибкость, поскольку операторы могут регулировать настройки для разных размеров бутылок и сортов пива. Хотя они не могут сравниться по скорости с автоматическими машинами, они обеспечивают надежную работу при мелкосерийном производстве.

3. Ручные фасовочные машины

Ручные разливочные машины предназначены для небольших пивоваренных заводов или домашних пивоваров, для которых контроль важнее скорости. Эти машины требуют полного участия оператора, включая размещение бутылок, инициирование розлива и герметизацию контейнеров.

Основным преимуществом ручных машин является их низкая стоимость, что делает их отличным выбором для пивоварен с минимальными производственными потребностями. Кроме того, они компактны и просты в использовании, не требуют много места и технических знаний. Однако ручные машины медленнее и менее эффективны, чем автоматизированные, поэтому они лучше подходят для ограниченных серий или специальных сортов пива.

4. Роторные фасовочные машины

Роторные фасовочные машины это высокоскоростные системы, предназначенные для крупных пивоваренных заводов с высокими производственными требованиями. Эти машины используют вращающуюся платформу для одновременного наполнения нескольких бутылок или банок, что значительно увеличивает производительность.

Роторные системы известны своей точностью и эффективностью. Они поддерживают постоянный уровень наполнения и минимизируют количество отходов даже на высоких скоростях. Многие модели оснащены такими передовыми функциями, как розлив под противодавлением и встроенные системы укупорки, обеспечивающие сохранение качества и газированности пива. Хотя роторные машины требуют значительных первоначальных инвестиций, их способность обрабатывать большие объемы делает их незаменимыми для крупных пивоваренных заводов.

5. Машины для розлива под давлением

Машины для розлива под противодавлением специально разработаны для газированных напитков, таких как пиво. Эти машины поддерживают одинаковое давление внутри бутылки и резервуара во время розлива, предотвращая чрезмерное пенообразование и потерю газированности.

Эти системы идеально подходят для пивоваренных заводов, которые ставят во главу угла качество и постоянство. Они широко используются как на малых, так и на крупных предприятиях, поскольку обеспечивают сохранение пивом заданного аромата и вкуса. Установки противодавления универсальны и могут работать с различными типами тары, включая бутылки и банки.

6. Вакуумные фасовочные машины

Вакуумные машины для розлива используют вакуум для втягивания пива в контейнер, уменьшая воздействие кислорода и сохраняя свежесть пива. Эти машины особенно полезны для высококачественного или специального пива, требующего длительного срока хранения.

Вакуумные системы очень эффективны для минимизации окисления, которое может ухудшить вкус пива. Они часто используются на небольших пивоварнях или для производства продукции премиум-класса. Хотя они не могут сравниться по скорости с роторными или автоматическими системами, их нацеленность на качество делает их ценным дополнением к любой пивоварне.

Разбираясь в различных типах машин для розлива пива, пивоваренные компании могут выбрать оборудование, которое наилучшим образом соответствует их производственным потребностям, бюджету и стандартам качества.

Наполнители пивных бутылок против наполнителей пивных банок

Выбирая между оборудованием для наполнения бутылок и банок, важно учитывать уникальные преимущества и проблемы каждого варианта.

- Наполнители для пивных бутылок: Разливочные машины для бутылок идеально подходят для пивоваренных заводов, которые отдают предпочтение традиционной упаковке. Стеклянные бутылки имеют первоклассный вид и ощущение, что делает их популярными для крафтовых и специальных сортов пива. Разливочные машины для бутылок часто оснащаются такими функциями, как системы противодавления для поддержания газированности и предотвращения пенообразования. Однако бутылки тяжелее и хрупче, что может увеличить стоимость доставки и требует осторожного обращения.

- Наполнители для пивных банок: Наполнители для банок набирают популярность благодаря легкости и прочности алюминиевых банок. Банки легче транспортировать, штабелировать и перерабатывать, что делает их экологически чистым выбором. Кроме того, они лучше защищают пиво от света и кислорода, сохраняя его качество. Машины для разлива пива в банки обычно работают быстрее, чем машины для разлива пива в бутылки, но для их работы может потребоваться дополнительное оборудование для герметизации и этикетирования.

Выбор между бутылками и банками часто зависит от брендинга, целевой аудитории и логистических соображений. Некоторые пивоварни инвестируют в гибридные системы, которые могут работать с обоими форматами для максимальной гибкости.

Выбор правильной машины для розлива

Выбор правильной разливочной машины имеет решающее значение для оптимизации работы вашей пивоварни. Вот ключевые факторы, которые необходимо учитывать:

- Объем производства: Оцените свои текущие и будущие производственные потребности. Небольшие пивоварни могут воспользоваться ручными или полуавтоматическими машинами, в то время как для крупных производств требуются полностью автоматизированные системы, чтобы удовлетворить спрос.

- Тип упаковки: Решите, что вы будете делать: бутылки, банки или и то, и другое. Это определит, нужен ли вам специальный наполнитель или гибридная система.

- Бюджет: Учитывайте как первоначальные затраты, так и долгосрочную экономию. Хотя автоматизированные машины требуют больших первоначальных инвестиций, они часто окупаются за счет повышения эффективности и снижения трудозатрат.

- Требования к пространству: Убедитесь, что машина вписывается в планировку вашего предприятия. Компактные модели доступны для небольших помещений, в то время как более крупные системы могут потребовать дополнительного места для эксплуатации и обслуживания.

- Параметры настройки: Ищите машины, которые позволяют регулировать размер бутылок или банок, уровень газирования и скорость производства. Такая гибкость гарантирует, что оборудование сможет адаптироваться к вашим меняющимся потребностям.

- Обслуживание и поддержка: Выбирайте машину от авторитетного производителя, который обеспечивает надежную поддержку клиентов и легкий доступ к запасным частям. Регулярное техническое обслуживание необходимо для поддержания бесперебойной работы оборудования.

Тщательно оценив эти факторы, вы сможете выбрать разливочную машину, которая будет соответствовать целям вашей пивоварни и обеспечит бесперебойный процесс упаковки.

Конфигурация линии розлива

Компоненты системы розлива

Система розлива состоит из нескольких взаимосвязанных компонентов, которые работают вместе, чтобы оптимизировать процесс упаковки. Каждый компонент играет важную роль в обеспечении эффективности, последовательности и качества продукции.

- Мойка для бутылок: Этот компонент очищает и дезинфицирует бутылки перед наполнением, удаляя пыль, мусор или загрязнения, чтобы обеспечить безопасность продукции.

- Разливочная машина: Ядро системы, разливочная машина переливает пиво из резервуаров в бутылки. В зависимости от типа пива и уровня карбонизации может использоваться гравитационная, противодавление или вакуумная система.

- Укупорочная машина: После розлива бутылки укупориваются крышками, чтобы сохранить газированность и предотвратить загрязнение. Укупорочные машины часто интегрируются с наполнителем для обеспечения бесперебойной работы.

- Этикетировочная машина: Этот компонент наносит этикетки на бутылки, обеспечивая надлежащее брендирование и соответствие нормативным требованиям.

- Конвейерная система: Конвейеры транспортируют бутылки между различными этапами процесса розлива, поддерживая постоянный поток и сокращая ручные операции.

- Инспекционная станция: Системы контроля качества проверяют правильность наполнения, надежность крышек и точность маркировки, гарантируя, что в продажу поступает только высококачественная продукция.

Интеграция машин для розлива и укупорки

Интеграция наполнения и укупорочные машины в единую систему повышает эффективность и снижает риск ошибок. Эти комбинированные системы обеспечивают непрерывный рабочий процесс, сводя к минимуму время простоя между наполнением и запечатыванием.

Синхронизируя процессы розлива и укупорки, пивоварни могут поддерживать постоянную скорость производства и обеспечивать герметичность бутылок сразу после розлива. Это снижает воздействие кислорода, сохраняя свежесть и аромат пива.

Современные интегрированные системы часто включают в себя расширенные функции, такие как автоматическая настройка для различных размеров бутылок и мониторинг в режиме реального времени для выявления проблем. Такой уровень автоматизации не только повышает точность, но и снижает трудозатраты, что делает его ценной инвестицией для пивоварен любого размера.

Оптимизация линии розлива для повышения эффективности

Чтобы максимально повысить эффективность линии розлива, рассмотрите следующие стратегии:

- Упорядочить рабочий процесс: Расположите компоненты в логической последовательности, чтобы минимизировать узкие места и обеспечить беспрепятственное прохождение бутылок через систему.

- Инвестируйте в автоматизацию: Автоматизированные системы сокращают ручной труд, повышают скорость производства и улучшают согласованность. Ищите машины с такими функциями, как самоочистка и автоматическая регулировка.

- Регулярное техническое обслуживание: Планируйте плановое техническое обслуживание, чтобы обеспечить бесперебойную работу оборудования и предотвратить непредвиденные простои. Регулярно очищайте и осматривайте такие компоненты, как конвейеры, наполнители и укупорщики.

- Мониторинг производительности: Используйте датчики и программное обеспечение для отслеживания ключевых показателей, таких как скорость производства, уровень заполнения и количество ошибок. Эти данные помогут выявить неэффективные процессы и направить их на улучшение.

- Обучение персонала: Убедитесь, что операторы хорошо обучены работе с оборудованием, чтобы свести к минимуму количество ошибок и увеличить производительность. Обеспечивайте постоянное обучение по мере внедрения новых технологий.

- Адаптация к спросу: Выбирайте гибкие системы, способные работать с бутылками разных размеров, сортами пива и объемами производства. Такая адаптивность позволит вам масштабировать производство по мере необходимости.

Сосредоточив внимание на этих областях, вы сможете создать линию розлива, которая будет работать эффективно, сократит количество отходов и обеспечит стабильное качество продукции для ваших клиентов.

Будущие тенденции в технологии розлива пива

Прогресс в области оборудования для розлива

Индустрия розлива пива быстро развивается, а новые технологии повышают эффективность, точность и качество. Современные машины для розлива все чаще оснащаются автоматикой и интеллектуальными функциями для оптимизации операций.

- Интеграция интеллектуальных датчиков и IoT: Современные машины теперь используют датчики и технологию Интернета вещей (IoT) для контроля уровня наполнения, давления и температуры в режиме реального времени. Это обеспечивает стабильное качество и сокращает количество отходов за счет раннего обнаружения проблем.

- Высокоскоростные системы розлива: Новое оборудование рассчитано на большие объемы производства без ущерба для точности. Такие системы идеально подходят для крупных пивоваренных заводов, стремящихся к расширению производства.

- Настраиваемые машины: Производители предлагают более гибкие машины, которые могут адаптироваться к различным размерам бутылок или банок, уровню газирования и типам пива. Такая универсальность особенно ценна для пивоваренных заводов, выпускающих разнообразную продукцию.

- Улучшенный контроль пенообразования: Передовые системы противодавления и вакуумные технологии снижают количество пены во время розлива, обеспечивают постоянный уровень наполнения и минимизируют потери продукта.

Устойчивое развитие при розливе пива

Экологичность становится главным приоритетом в пивной индустрии, и технология розлива адаптируется к этим требованиям.

- Энергоэффективные машины: Современное оборудование для розлива рассчитано на меньшее потребление энергии, что снижает углеродный след от процесса розлива. Пивоваренные компании все чаще инвестируют в оборудование с энергосберегающими функциями.

- Перерабатываемая и легкая упаковка: Системы розлива оптимизируются для использования экологически чистых материалов, таких как легкие алюминиевые банки и стеклянные бутылки, пригодные для вторичной переработки. Такие варианты сокращают количество отходов и привлекают экологически сознательных потребителей.

- Сохранение водных ресурсов: Усовершенствованные системы очистки и розлива используют меньше воды, решая одну из самых серьезных проблем пивоваренной промышленности в области устойчивого развития. Некоторые машины даже перерабатывают воду, используемую в процессе очистки.

- Углеродно-нейтральные операции: Пивоваренные компании внедряют углеродно-нейтральные линии розлива, используя возобновляемые источники энергии и компенсируя выбросы. Эта тенденция согласуется с более широкими целями отрасли по снижению воздействия на окружающую среду.

Возвышение крафтового пивоварения и его влияние

Бум ремесленного пивоварения существенно повлиял на технологию розлива пива, вызвав спрос на более компактные и универсальные системы.

- Компактные фасовочные машины: Ремесленные пивоварни часто работают в ограниченном пространстве, поэтому производители разрабатывают компактные машины, которые обеспечивают высокую производительность, не требуя больших помещений.

- Гибкость при изготовлении мелких партий: Крафтовые пивовары часто экспериментируют с новыми вкусами и стилями, поэтому им требуются системы розлива, способные эффективно работать с небольшими партиями. Машины с возможностью быстрой переналадки становятся незаменимыми.

- Ориентируйтесь на качество: Крафтовые пивовары отдают предпочтение качеству, а не количеству, что приводит к увеличению спроса на оборудование, которое минимизирует воздействие кислорода и сохраняет уникальные характеристики пива.

- Дифференциация бренда: Ремесленные пивоварни часто используют оригинальную упаковку, чтобы выделиться. Машины для розлива теперь разработаны с учетом нестандартных форм, размеров и требований к этикетке бутылок.

Эти тенденции свидетельствуют о том, что технология розлива пива развивается в соответствии с потребностями динамичной и экологически сознательной отрасли.

Часто задаваемые вопросы

Вопрос: Что такое небольшая машина для розлива пива?

A: Небольшая машина для розлива пива - это оборудование для розлива, предназначенное для эффективного розлива пива в бутылки или банки. Оно идеально подходит для небольших пивоваренных заводов, которым требуется надежное оборудование для упаковки своих напитков. В зависимости от производственных потребностей эти машины могут быть полуавтоматическими или полностью автоматизированными.

Вопрос: Как работает машина для розлива пива?

О: Пиворазливочная машина разливает пиво в бутылки или банки с помощью клапана розлива. Часто используется противодавление, чтобы предотвратить потерю карбонизации в процессе. Многие машины интегрируются с укупорочными системами для немедленной герметизации тары, что обеспечивает сохранение качества и свежести пива.

Вопрос: С какими типами тары может работать небольшая машина для розлива пива?

О: Небольшая машина для розлива пива может работать с различными емкостями, включая стеклянные бутылкиалюминиевые банки и даже кеги. Эти машины могут быть настроены на различные размеры и требования к наполнению, что делает их универсальными для различных потребностей в упаковке.

Вопрос: Каковы преимущества использования автоматической машины для розлива пива?

A: Автоматический машина для розлива пива повышает эффективность и обеспечивает последовательность процесса розлива. Он сокращает ручной труд, минимизирует риски загрязнения и обеспечивает более высокие темпы производства, позволяя пивоварням упаковывать больше пива за меньшее время.

Вопрос: Можно ли использовать небольшую машину для розлива пива для газированных напитков?

О: Да, небольшая машина для розлива пива предназначена для работы с газированными напитками. В нем используются такие методы, как розлив под противодавлением, для предотвращения чрезмерного пенообразования и поддержания целостности газировки на протяжении всего процесса.

Вопрос: Какова типичная производственная мощность небольшой машины для розлива пива?

О: Производительность небольшой машины для розлива пива зависит от модели и технических характеристик. Многие машины могут разливать несколько сотен бутылок или банок в час, что делает их подходящими для небольшого производства. Более продвинутые модели могут иметь более высокую производительность в зависимости от уровня автоматизации.

В: Как выбрать подходящее оборудование для розлива пива для моей пивоварни?

О: Чтобы выбрать правильный оборудование для розлива пиваУчитывайте масштабы производства, тип тары (бутылки или банки) и желаемый уровень автоматизации. Оцените надежность поставщика и убедитесь, что оборудование совместимо с имеющейся у вас пивоваренной установкой. Изучение характеристик оборудования и сравнение вариантов поможет вам принять взвешенное решение.

Вопрос: Какое техническое обслуживание требуется для небольшой машины для розлива пива?

О: Регулярное техническое обслуживание имеет решающее значение для поддержания эффективности и долговечности небольшой машины для розлива пива. Задачи включают в себя регулярную очистку, проверку деталей на предмет износа, а также обеспечение правильной работы разливочных клапанов и укупорочных механизмов. Соблюдение рекомендаций производителя по техническому обслуживанию поможет предотвратить поломки и сохранить стабильное качество продукции.

Заключительное резюме

Эволюция оборудования для розлива пива в бутылки изменила пивоваренную отрасль, предлагая решения, которые повышают эффективность, сохраняют качество продукции и отвечают целям устойчивого развития. От понимания тонкостей процесса розлива до выбора правильного оборудования и оптимизации линии розливаВ распоряжении пивоваренных заводов есть множество инструментов для оптимизации работы. Поскольку отрасль продолжает внедрять такие достижения, как интеграция IoT, энергоэффективные системы и гибкие конструкции, технология розлива пива способна удовлетворить растущие потребности как крупных производителей, так и ремесленных пивоваров. Используя эти инновации, пивоварни смогут выпускать исключительную продукцию, оставаясь адаптированными к постоянно меняющемуся рынку.