Знаете ли вы, что даже незначительное повышение эффективности розлива жидкостей может сэкономить производителям тысячи долларов в год? В отраслях, где крупносерийное производство является нормой, важна каждая капля. Гравитационные фасовочные машины играют ключевую роль в обеспечении точного и эффективного дозирования жидкостей, что делает их краеугольным камнем современных упаковочных операций.

Гравитационные разливочные машины используют естественную силу тяжести для перекачки жидкостей в контейнеры, обеспечивая простое, но высокоэффективное решение для маловязких продуктов, таких как вода, соки и моющие растворы. Простая конструкция делает их простыми в эксплуатации, экономически эффективными и не требующими особого ухода по сравнению с более сложными системами. Эти качества делают гравитационные наполнители популярным выбором для производителей, стремящихся оптимизировать свою деятельность без значительных затрат.

В этой статье мы рассмотрим ключевые принципы работы гравитационных разливочных машин, их преимущества и лучшие практики для достижения максимальной производительности. Мы также рассмотрим наиболее распространенные области их применения, чтобы помочь вам понять, почему они остаются надежным решением для эффективного розлива жидкостей. Если вы новичок в гравитационном розливе или хотите оптимизировать имеющееся оборудование, это руководство поможет вам извлечь максимум пользы из этой надежной технологии.

Оглавление

ToggleОсновные принципы гравитационного наполнения

Гравитационные разливочные машины работают по простому, но эффективному принципу: используя естественную силу тяжести для перемещения жидкости из резервуара в контейнеры. Такой простой подход делает их надежными, экономически эффективными и простыми в обслуживании. Давайте разберемся, как гравитация управляет процессом, в чем разница между наполнением по времени и по уровню и какие продукты лучше всего подходят для этого метода.

Как гравитация управляет процессом

Гравитационный розлив основывается на высоте и давлении для перемещения жидкости в контейнеры. Процесс начинается с резервуара, расположенного над контейнерами, создавая необходимое давление для стекания жидкости вниз. Когда открывается клапан наполнения, гравитация втягивает жидкость в расположенный под ним контейнер.

Вытяжная трубка играет важную роль в этой установке, вытесняя воздух из контейнера по мере заполнения его жидкостью. Это обеспечивает плавный, непрерывный поток и предотвращает такие проблемы, как воздушные карманы или неравномерное заполнение. Простота этой конструкции сводит к минимуму механическую сложность, что делает гравитационные наполнители простыми в эксплуатации и обслуживании.

Например, представьте, что вы наполняете ряд бутылок с водой. Резервуар удерживает жидкость на высоте, а когда каждая бутылка перемещается на место, клапан открывается, позволяя силе тяжести выполнить свою работу. Трубка для выпуска воздуха обеспечивает выход воздуха, в результате чего каждая бутылка наполняется до нужного уровня или объема.

Время в зависимости от уровня заполнения

Гравитационные фасовочные машины могут работать по двум различным методикам: наполнение по времени и наполнение по уровню. Каждый из этих методов отвечает конкретным потребностям, в зависимости от продукта и требований к упаковке.

Наполнение по времени

Наполнение по времени измеряет объем жидкости, контролируя время, в течение которого клапан остается открытым. Этот метод лучше всего подходит для жидкостей с постоянной вязкостью, таких как вода или моющие растворы. Например, если жидкость течет с постоянной скоростью, открытие клапана на пять секунд приведет к постоянному заполнению каждого контейнера одинаковым объемом.

Наполнение на основе уровня

Наполнение по уровню направлено на достижение визуальной однородности, особенно в прозрачных контейнерах, таких как бутылки для напитков. В этом методе используется система перелива, обеспечивающая одинаковый уровень наполнения всех контейнеров, независимо от незначительных различий в их размерах и форме. Излишки жидкости стекают обратно в резервуар, сохраняя полированный, профессиональный вид продукции, выставленной на полках магазинов.

Пригодность продукции

Гравитационные разливочные машины отлично справляются с жидкостями низкой вязкости, которые свободно текут, такими как вода, соки и негазированные напитки. Простота и эффективность делают их оптимальным выбором для крупносерийных производственных линий, работающих с такими типами продуктов.

Однако гравитационные наполнители подходят не для всех случаев. Густые жидкости, такие как мед или арахисовое масло, требуют более силовых методов, например поршневого наполнения, для обеспечения равномерного наполнения. Аналогично, пенистые продукты или продукты с твердыми частицами, такие как газированные напитки или супы, могут создать проблемы для гравитационных наполнителей, поскольку пена или твердые частицы могут нарушить поток и привести к несовместимым результатам.

Поняв основные принципы гравитационного наполнения, вы сможете определить, соответствует ли этот метод характеристикам вашего продукта и производственным целям.

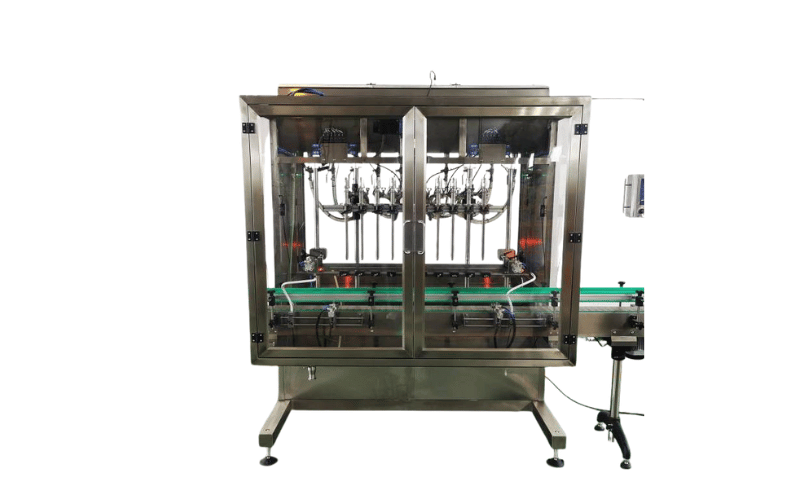

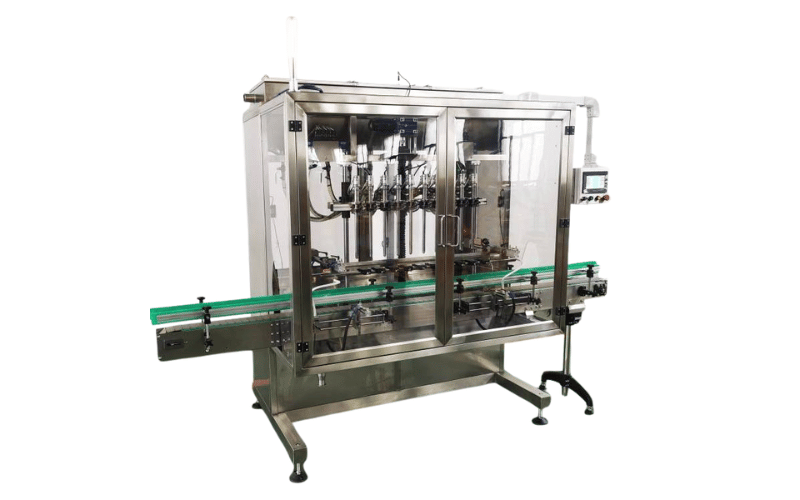

Основные компоненты и работа

Понимание компонентов и работы гравитационной фасовочной машины необходимо для оптимизации ее работы и обеспечения стабильных результатов. Каждая деталь машины играет определенную роль в процессе розлива, работая вместе для обеспечения точности и эффективности. Давайте разберем основные компоненты, поэтапный цикл наполнения, а также важность типов клапанов и выбора материала.

Компоненты машин

Гравитационные фасовочные машины состоят из нескольких важнейших компонентов, каждый из которых предназначен для выполнения определенных задач в процессе фасовки:

- Питательный резервуар (водохранилище): Расположенный над контейнерами резервуар удерживает жидкость и обеспечивает необходимую высоту, чтобы гравитация могла управлять потоком.

- Заправочные форсунки: Эти форсунки контролируют подачу жидкости в контейнеры, обеспечивая точность и минимизируя проливание.

- Механизмы уплотнения: Эти механизмы предотвращают протечки в процессе наполнения, надежно герметизируя соединение между соплом и контейнером.

- Системы контроля: Современные гравитационные наполнители используют программируемые логические контроллеры (ПЛК) для управления временем, расходом и другими параметрами, обеспечивая постоянную производительность.

- Системы обработки контейнеров: Звездные колеса и конвейеры направляют контейнеры на место под заливные форсункиПоддерживая плавный и эффективный рабочий процесс.

Каждый из этих компонентов работает в гармонии, создавая бесперебойный процесс розлива, от хранения жидкости до обработки контейнеров.

Пошаговый цикл заполнения

Цикл розлива в гравитационной фасовочной машине проходит в точной последовательности, обеспечивающей точность и эффективность:

- Позиционирование контейнеров: Система перемещения контейнеров, например, конвейер или звездочка, перемещает контейнеры в положение под форсунками для наполнения. Датчики определяют наличие каждого контейнера, чтобы обеспечить правильное выравнивание.

- Активация клапана: Как только контейнер установлен, система управления открывает клапан наполнения, позволяя жидкости перетекать из резервуара в контейнер.

- Поток жидкости: Под действием силы тяжести жидкость движется вниз, заполняя емкость до нужного уровня или объема. Вытяжные трубки вытесняют воздух, чтобы предотвратить прерывание потока.

- Закрытие клапана: Когда контейнер достигает заданного уровня заполнения, система управления закрывает клапан, останавливая поток жидкости.

Датчики и ПЛК играют важнейшую роль в этом процессе, контролируя уровень наполнения и гарантируя, что в каждый контейнер будет налито нужное количество жидкости. Такой уровень автоматизации снижает количество ошибок и повышает эффективность производства.

Типы клапанов и выбор материала

Тип клапана, используемого в гравитационной разливочной машине, оказывает значительное влияние на ее производительность и пригодность для различных продуктов.

- Клапаны с поднимающимся штоком: Эти клапаны обычно используются в гравитационных наполнителях для точного запуска и остановки потока жидкости. Их конструкция сводит к минимуму количество капель и обеспечивает чистый, контролируемый процесс наполнения.

- Материальные соображения: Материалы, используемые в компонентах машины, должны соответствовать разливаемому продукту. Например, гигиенические материалы, такие как нержавеющая сталь, необходимы для пищевых продуктов и напитков, а химически стойкие материалы - для агрессивных жидкостей, таких как чистящие средства.

Правильный выбор типа клапана и материалов обеспечивает эффективную работу машины и соответствие промышленным стандартам безопасности и гигиены.

Понимая основные компоненты и принцип работы гравитационных фасовочных машин, вы сможете оптимизировать их работу и обеспечить соответствие требованиям вашей производственной линии.

Производительность, обслуживание и точность

Производительность гравитационной разливочной машины зависит от ее способности обеспечивать точные, эффективные и гигиеничные результаты. Чтобы достичь этого, производители должны понимать факторы, влияющие на точность, балансировать между скоростью и точностью, а также уделять первоочередное внимание регулярному техническому обслуживанию. Давайте подробно рассмотрим эти аспекты и дадим практические рекомендации, которые помогут вашей машине работать как можно лучше.

Факторы, влияющие на точность

На точность работы гравитационной фасовочной машины могут влиять несколько факторов, устранение которых обеспечивает стабильность результатов:

- Консистенция жидкости Температура и вязкость: Перепады температуры могут изменять вязкость жидкости, влияя на скорость ее потока. Например, сироп, плавно текущий при температуре 80°F, может значительно замедлиться при температуре 60°F, что приведет к недоливу. Поддержание стабильной температуры продукта очень важно для точного розлива.

- Колебания головного давления: Уровень жидкости в резервуаре напрямую влияет на давление напора. По мере опустошения резервуара давление снижается, что может привести к нестабильному заполнению. Установка датчика уровня или поддержание постоянного уровня жидкости может уменьшить эту проблему.

- Состояние сопла: Изношенные или поврежденные насадки могут стать причиной капель, протечек или неравномерного потока. Регулярный осмотр и замена форсунок обеспечивают бесперебойную работу.

- Калибровка для настройки времени и уровня: Правильная калибровка систем наполнения по времени или по уровню очень важна. Для систем, основанных на времени, убедитесь, что клапан остается открытым в течение нужного времени. Для систем, основанных на уровне, проверьте правильность работы механизма перелива для достижения равномерного уровня наполнения.

Скорость и пропускная способность

Скорость производства - важнейший фактор для достижения поставленных целей, но она должна быть сбалансирована с точностью, чтобы избежать отходов и переделок.

- Количество форсунок: Количество форсунок напрямую влияет на скорость производства. Например, машина с четырьмя форсунками может одновременно заполнять четыре контейнера, что вдвое превышает производительность системы с двумя форсунками. Добавление большего количества форсунок увеличивает скорость, но может потребовать дополнительной калибровки для поддержания точности.

- Баланс между скоростью и точностью: Максимальная скорость работы машины может снизить точность розлива, особенно для жидкостей с непостоянной вязкостью. Регулировка скорости потока и контроль работы системы помогают найти правильный баланс между скоростью и точностью.

При больших объемах работ стоит подумать о приобретении многосопловой системы с усовершенствованным управлением, чтобы оптимизировать скорость и точность.

Обслуживание и гигиена

Правильное техническое обслуживание и гигиена не являются обязательными, особенно в таких отраслях, как производство продуктов питания и напитков, где высок риск загрязнения.

- Системы очистки на месте (CIP): Системы CIP упрощают процесс очистки, позволяя операторам очищать внутренние компоненты оборудования без его разборки. Это особенно важно для пищевых производств, где тщательная очистка предотвращает рост бактерий и обеспечивает соответствие стандартам безопасности.

- Регулярный осмотр и санитарная обработка: Регулярно осматривайте компоненты, такие как насадки, уплотнения и клапаны, на предмет износа или скопления остатков. Дезинфекция этих деталей предотвращает перекрестное загрязнение, особенно при переходе от одного продукта к другому. Например, машина, разливающая в один день апельсиновый сок, а на следующий - холодный чай, должна быть тщательно очищена, чтобы избежать передачи вкуса.

Устранение распространенных проблем

Даже самые исправные машины могут столкнуться с проблемами. Их своевременное устранение сводит к минимуму время простоя и обеспечивает стабильную работу:

- Неточности в заполнении: Проверьте, нет ли изменений в вязкость жидкости, давление напора или настройки калибровки для обеспечения точного заполнения. Регулировка этих факторов часто решает проблему.

- Утечки: Осмотрите форсунки, уплотнения и клапаны на предмет повреждений или износа. Замена неисправных компонентов предотвращает дальнейшие утечки.

- Проблемы с выравниванием контейнеров: Неправильное расположение контейнеров может привести к проливу или неполному заполнению. Убедитесь, что система перемещения контейнеров, например конвейеры или колеса-звездочки, отрегулирована должным образом и работает без сбоев.

Понимая факторы, влияющие на производительность, соблюдая строгий график очистки и заблаговременно решая проблемы, вы сможете добиться максимальной эффективности и точности работы вашей гравитационной разливочной машины.

Сравнение гравитационных филлеров с другими технологиями

Выбор правильной технологии розлива требует понимания того, как каждый метод работает в различных условиях. Гравитационные наполнители отличаются простотой и экономичностью, но для конкретных продуктов или производственных целей могут лучше подходить другие технологии. Давайте сравним гравитационные наполнители с напорными, поршневыми и переливными системами наполнения, чтобы помочь вам принять обоснованное решение.

Гравитационное наполнение по сравнению с наполнением под давлением

Наполнитель под давлением применяется там, где не справляется гравитационный наполнитель, особенно для густых или пенистых продуктов. В то время как гравитационные наполнители полагаются исключительно на естественную силу тяжести, наполнители под давлением используют дополнительную силу для проталкивания жидкостей в контейнеры. Это делает их идеальными для таких продуктов, как газированные напитки, которые требуют контролируемого давления для предотвращения вспенивания, или вязких жидкостей, таких как сиропы и масла, которые не текут свободно.

С точки зрения стоимости и сложности гравитационные наполнители являются более простым вариантом. В них меньше движущихся частей, что делает их более простыми в обслуживании и доступными в эксплуатации. Напорные наполнители, напротив, включают в себя более сложные компоненты, такие как резервуары под давлением и специализированные форсунки, что увеличивает как первоначальные инвестиции, так и текущие требования к обслуживанию.

Если ваш продукт жидкий и свободно текущий, гравитационное наполнение - простое и бюджетное решение. Однако для более густых или пенистых жидкостей наполнение под давлением обеспечивает дополнительную силу, необходимую для получения стабильных результатов.

Гравитационное и поршневое наполнение

Поршневые наполнители - это оптимальный выбор для точного объемного дозирования, особенно для густых продуктов, таких как арахисовое масло, кремы или густые супы. В отличие от гравитационных наполнителей, которые работают по времени или по уровню, поршневые наполнители используют цилиндр и поршневой механизм для измерения и дозирования точных объемов жидкости. Такой уровень точности делает их незаменимыми при производстве дорогостоящих или вязких продуктов, где точность имеет решающее значение.

Однако поршневые наполнители имеют более жесткие требования к очистке и обслуживанию. Поршень и цилиндр необходимо разбирать и тщательно чистить, особенно при переходе с одного продукта на другой. Гравитационные наполнители, напротив, легче чистить и обслуживать благодаря их более простой конструкции.

Если ваша производственная линия работает со смесью жидких и густых жидкостей, возможно, вам стоит рассмотреть возможность использования обеих технологий. Гравитационные наполнители могут работать со свободно текущими продуктами, в то время как поршневые наполнители позаботьтесь о более толстых и сложных.

Гравитационное и переливное наполнение

Наполнение через перелив является предпочтительным методом для достижения визуального единообразия в прозрачных контейнерах, таких как бутылки для напитков или шампуней. Эта система обеспечивает одинаковый уровень наполнения каждого контейнера, даже при незначительных различиях в размере или форме контейнера. Гравитационные наполнители, хотя и не предназначены специально для этой цели, могут использовать вариации перелива для достижения аналогичных результатов.

Ключевое различие заключается в обработке излишков жидкости. Наполнители с переливом предназначены для возврата излишков жидкости в резервуар, обеспечивая чистый и полированный внешний вид. Гравитационные наполнители с переливом могут имитировать эту функцию, но не могут обеспечить такой же уровень точности для прозрачных контейнеров.

Если внешний вид продукта является приоритетом, например, при розничной торговле напитками, то переливной розлив обеспечивает эстетическое постоянство, которого ожидают потребители. Для менее чувствительных к внешнему виду задач гравитационные наполнители остаются экономичной и эффективной альтернативой.

Сравнивая гравитационные наполнители с напорными, поршневыми и переливными системами, вы сможете лучше понять, как каждая технология вписывается в ваши производственные потребности. У каждого метода есть свои сильные стороны, и правильный выбор зависит от характеристик вашего продукта, производственных целей и бюджета.

Инновации в технологии гравитационного наполнения

Технология гравитационного розлива значительно продвинулась вперед, развиваясь в соответствии с требованиями современного производства. Сегодняшние машины более интеллектуальны, эффективны и экологичны, что делает их незаменимыми для предприятий, стремящихся сохранить конкурентоспособность. Давайте рассмотрим, как автоматизация, электроника и экологичность меняют гравитационные системы розлива.

Автоматизация и электроника

Современные гравитационные наполнители используют автоматику и передовую электронику для обеспечения непревзойденной точности и эффективности. Датчики теперь играют важнейшую роль в контроле каждого этапа процесса розлива. Например, датчики уровня жидкости в резервуаре обеспечивают постоянное давление напора, а датчики обнаружения контейнеров предотвращают проливание, подтверждая правильное выравнивание перед началом розлива.

Программируемые настройки, управляемые с помощью удобных панелей управления, позволяют операторам точно настраивать такие параметры, как время наполнения, скорость потока и активация форсунок. Такой уровень настройки гарантирует, что машина легко адаптируется к различным продуктам и размерам контейнеров.

Интеграция искусственного интеллекта (ИИ) делает автоматизацию еще одним шагом вперед. Системы искусственного интеллекта анализируют данные в режиме реального времени, чтобы выявить неэффективные процессы, такие как непоследовательное заполнение или капание из сопла, и немедленно вносят коррективы для поддержания оптимальной производительности. Например, если вязкость жидкости меняется из-за перепадов температуры, ИИ может автоматически перекалибровать время заполнения, обеспечивая точность без ручного вмешательства.

Характеристики устойчивости

Экологичность стала движущей силой при разработке гравитационных фасовочных машин: производители отдают предпочтение энергоэффективности и экологически чистым материалам.

Энергоэффективные конструкции, такие как использование частотно-регулируемых приводов (ЧРП), оптимизируют скорость вращения двигателя и снижают потребление энергии во время работы. Это не только снижает эксплуатационные расходы, но и минимизирует воздействие машины на окружающую среду. Например, гравитационный шприц, оснащенный VFD, может регулировать потребление энергии в зависимости от скорости производства, обеспечивая отсутствие излишней траты энергии во время медленных циклов.

Экологически чистые материалы и процессы также набирают обороты. Многие машины теперь оснащаются компонентами из нержавеющей стали, которые не только долговечны, но и подлежат вторичной переработке. Кроме того, производители внедряют модульные конструкции, которые позволяют легко модернизировать или заменять детали, тем самым продлевая срок службы оборудования и сокращая количество отходов.

Эти инновации делают гравитационные шприцы не просто экономически выгодным решением - они становятся экологичным выбором для предприятий, стремящихся соответствовать экологическим целям, сохраняя при этом высокие производственные стандарты.

Благодаря интеграции передовой автоматизации и приоритету устойчивости технология гравитационного розлива продолжает развиваться, предлагая производителям более инновационные, экологичные и эффективные решения для их производственных линий.

Вопросы и ответы: Общие вопросы о гравитационном наполнении

В: Какие виды продукции лучше всего подходят для гравитационного наполнения?

О: Гравитационный розлив лучше всего подходит для жидкостей с низкой вязкостью, которые свободно текут, таких как вода, соки, негазированные напитки, чистящие растворы и легкие масла. Эти продукты не требуют дополнительных усилий для перемещения по системе, что делает гравитационные наполнители эффективным и экономичным выбором.

Вопрос: Как температура влияет на точность гравитационного наполнителя?

О: Изменение температуры может привести к изменению вязкости жидкости, что напрямую влияет на скорость потока и точность заполнения. Например, жидкость, которая легко течет при высокой температуре, может замедлиться при охлаждении, что приведет к недоливу. Для поддержания точности очень важно контролировать и стабилизировать температуру продукта в процессе розлива.

В: Могут ли гравитационные разливочные машины работать с газированными напитками?

О: Гравитационные наполнители не идеальны для газированных напитков. Естественный поток жидкости в гравитационной системе может вызвать чрезмерное пенообразование, что приведет к нестабильному наполнению и потере продукта. Системы розлива под давлением лучше подходят для газированных продуктов, поскольку они контролируют поток и поддерживают уровень газирования.

Вопрос: Каков типичный срок службы гравитационной разливочной машины?

О: При надлежащем обслуживании гравитационная разливочная машина может прослужить от 10 до 15 лет и более. Регулярная очистка, своевременная замена изнашивающихся компонентов, таких как уплотнения и форсунки, и соблюдение графиков технического обслуживания обеспечивают длительный срок эксплуатации.

В: Как часто следует калибровать гравитационный наполнитель?

О: Калибровку гравитационного шприца следует проводить каждый раз, когда вы меняете продукты, корректируете объемы наполнения или замечаете несоответствия в наполнении. Для обеспечения стабильной работы планируйте плановые проверки калибровки не реже одного раза в месяц, в зависимости от производственных требований.

В: Используются ли в гравитационных наполнителях насосы?

О: Нет, в гравитационных наполнителях не используются насосы. Они полагаются на естественную силу тяжести для перемещения жидкости из резервуара в контейнеры. Такая простота делает их экономически эффективными и простыми в обслуживании по сравнению с системами на основе насосов.

В: В чем разница между заполнением по времени и заполнением по уровню?

О: Временной розлив измеряет объем жидкости, контролируя, как долго клапан остается открытым, что делает его идеальным для продуктов с постоянной вязкостью. Заполнение по уровню, с другой стороны, гарантирует, что все контейнеры будут заполнены до одного и того же визуального уровня, что особенно важно для прозрачных контейнеров, таких как бутылки с напитками. При заполнении по времени приоритет отдается точности объема, в то время как при заполнении по уровню основное внимание уделяется эстетическому соответствию.

Заключение: Значение гравитационных фасовочных машин

Гравитационные фасовочные машины отличаются непревзойденной простотой, экономичностью и универсальностью, что делает их надежным выбором для многих производителей. Их простая конструкция обеспечивает эффективную и последовательную упаковку жидкостей, особенно для маловязких и непенящихся жидкостей. Если вы ищете надежное решение для оптимизации производственной линии, рассмотрите гравитационные шприцы как практичный и эффективный вариант.