Modular filling systems are revolutionizing automatic liquid filling machinery. As manufacturing demands evolve, the advantages of automation become undeniable. These adaptable systems offer the flexibility and efficiency needed to stay competitive. This guide explores the key benefits, applications, and future-proof adaptability of modular systems, showing why they are a superior choice for modern production lines. By understanding their design and function, you can see how they drive productivity and growth.

Table of Contents

ToggleUnderstanding Modular Filling Systems

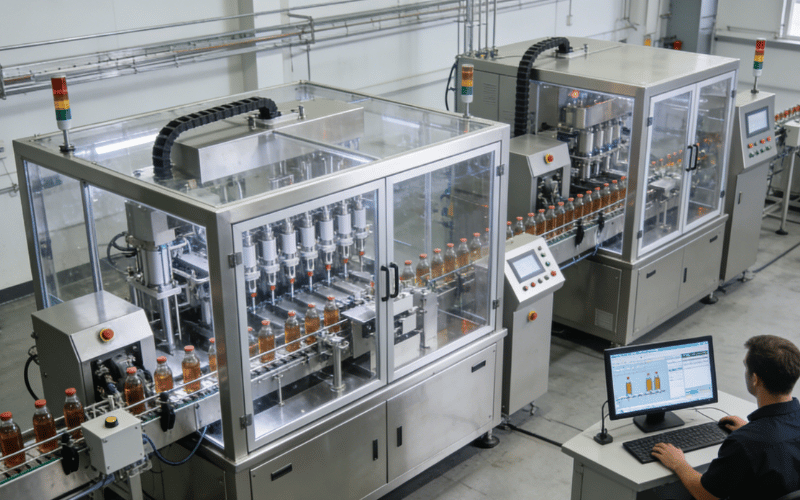

A modular filling system is an automated production line composed of independent, interchangeable units, or “modules.” Unlike traditional, fixed liquid filling machines, a modular design offers incredible flexibility and scalability. Businesses can start with essential modules and add more as their needs grow. This “plug-and-play” approach empowers companies to adapt quickly to new products, containers, or production volumes, making it a cornerstone of modern, agile manufacturing.

Components of a Modular Filling Machine

Each component in a modular system plays a specific role, working together for a seamless process. The beauty of these modular components is that they can be swapped or upgraded to meet different production requirements. Key parts include:

- Filling Nozzles: These are the core filling mechanisms, chosen based on liquid viscosity and desired speed.

- Capping Units: These modules automatically apply and tighten caps, with options for screw, snap, or press-on styles.

- Conveyor Systems: The backbone of the line, moving containers smoothly between stations.

- Sensors: These monitor fill levels, cap placement, and line speed to ensure quality and prevent errors.

Benefits of Modular Design in Liquid Filling

As industries evolve to meet growing consumer demands, the need for efficient, reliable, and scalable production solutions has never been greater. Modular filling systems, with their innovative design and automated capabilities, are at the forefront of this transformation. By combining the flexibility of modularity with the precision of automation, these systems address the challenges of modern manufacturing, offering unparalleled benefits in efficiency, cost savings, and product quality. Let’s explore how modular design and automation work together to revolutionize liquid filling processes.

Advantages of Automation in Filling Machines

Automated filling machines bring a new level of performance to any production floor. By automating repetitive tasks, these systems deliver significant gains in efficiency, accuracy, and consistency that are impossible to achieve with manual labor. For instance, precision filling technology ensures every container receives the same amount of product, drastically reducing costly overfills and waste. This level of control minimizes human error, improves product quality, and enhances workplace safety by removing operators from potentially hazardous tasks, making automation an essential tool for scaling operations.

Increased Efficiency with Automated Filling

Automated modular systems are built for maximum efficiency. They streamline the entire production process, dramatically increasing throughput while reducing the downtime associated with manual changeovers. The continuous, synchronized workflow eliminates bottlenecks, allowing a higher volume of products to be filled in less time. This boost in productivity means faster order fulfillment, greater capacity, and improved profitability, making automation a key driver of lean manufacturing.

Cost Savings Through Automation

While there is an initial investment, cost-effective filling solutions deliver substantial long-term savings. Automation significantly reduces labor expenses, as one operator can oversee an entire line that runs 24/7. These systems also minimize product waste through precise filling, saving money on lost resources. Lower energy consumption and reduced maintenance needs further decrease operational overhead, providing a clear and compelling return on investment over the equipment’s lifespan.

Improved Accuracy and Consistency

Automated systems are vital for achieving unparalleled accuracy and consistent production. Using advanced sensors and precision filling mechanisms, these machines eliminate the variability of manual processes. Every container is filled to the same level, ensuring product uniformity that builds consumer trust and meets regulatory standards. This repeatable, accurate filling process guarantees a professional final product and reinforces your brand’s quality and reliability.

Applications of Modular Liquid Filling Solutions

The versatility of modular liquid filling systems makes them indispensable across a wide range of industries. By combining precision, adaptability, and efficiency, these systems cater to the unique demands of sectors ranging from food and beverage to pharmaceuticals and cosmetics. Their ability to handle diverse product types and integrate seamlessly into existing production lines ensures they remain a cornerstone of modern manufacturing. Let’s dive into the specific industries that benefit most from these innovative solutions.

Industries Benefiting from Automated Filling

The industry applications for automated filling solutions are vast, as they provide the speed and precision needed in high-demand sectors. They are particularly beneficial for:

- Food and Beverage: Ensuring hygienic handling and consistent portion control for products like sauces, juices, and dressings.

- Pharmaceuticals: Offering sterile, precise dispensing for medicines where accuracy and compliance are non-negotiable.

- Cosmetics: Handling diverse viscosities of lotions and creams while maintaining the integrity and appearance of the final product.

Customizing Filling Solutions for Different Liquids

A key strength of modular systems is their adaptability to different liquid properties. Whether you are working with a thin, water-like substance, a thick paste, or a foamy product, these systems can be configured for optimal performance. Customized filling solutions are created by selecting the right modules, such as specialized nozzles or pumps, to handle challenges like viscosity or temperature sensitivity. This adaptability ensures accurate fills and prevents issues like spills or product degradation.

Integration with Packaging Lines

Modular filling systems are designed for seamless integration into packaging lines. Their “plug-and-play” nature allows them to connect effortlessly with other equipment, such as capping, labeling, and conveyor modules. When synchronized, the entire line operates as a single, cohesive unit. This eliminates bottlenecks between stations, creating a smoother workflow, reducing manual handling, and increasing overall production efficiency from start to finish.

Adaptability of Modular Systems

The adaptability of modular systems is a game-changer for manufacturers looking to stay competitive in dynamic markets. These systems are designed to evolve alongside your business, offering unmatched flexibility and scalability to meet changing production demands. Whether you’re scaling up for higher output or diversifying your product range, modular designs provide the tools to adapt without overhauling your entire operation. Let’s explore how these systems enable seamless growth and versatility in production.

Scaling Production with Modular Design

Scalable filling systems are designed to grow with your business. Instead of investing in a massive, fixed machine, you can start with a basic setup and add modules as your production volume increases. This production flexibility allows you to scale up by adding more filling heads to increase speed or integrating an automated case packer to handle higher output. This incremental approach is cost-effective, minimizes disruption, and ensures your machinery always matches your current needs.

Flexibility for Different Product Formats

Modular systems provide flexible filling solutions to handle diverse packaging with minimal downtime. Operators can quickly adjust guide rails, swap nozzles, and reconfigure settings to switch between various formats. This adaptability is perfect for brands with diverse portfolios. Examples include:

- Glass and plastic bottles of varying shapes.

- Flexible pouches and stand-up bags.

- Rigid aluminum cans and jars.

Future-Proofing Your Filling Machinery

Investing in modular technology is a strategic way to create future-proof filling systems. As technology and industry standards evolve, you don’t need to replace the entire line; you can upgrade individual modules. This enables the easy integration of innovations such as IoT sensors for predictive maintenance or advanced vision systems for quality control. This long-term adaptability saves money and ensures your production line remains modern and compliant for years to come.

FAQs About Modular Filling Systems

Why Choose Modular Filling Systems for My Filling Process?

Modular filling systems offer unmatched precision, scalability, and efficiency. Key modular filling benefits include the ability to adapt to new products quickly, reduce costly downtime, and ensure consistent quality. They are a cost-effective solution for businesses looking to grow and respond to market changes without replacing their entire production line.

How Do Modular Systems Minimize Downtime and Improve Productivity?

These systems achieve minimal downtime because individual modules can be serviced or replaced without shutting down the entire line. Quick, tool-less changeovers between products or container sizes also contribute to increased productivity. This continuous operation ensures you can meet production targets and maintain a high level of efficiency.

Are Modular Filling Systems Suitable for Food, Pharmaceutical, and Cosmetic Industries?

Yes, absolutely. Hygienic filling systems are designed with sanitary materials and easy-to-clean components, making them ideal industry-specific solutions. They can be configured to meet the strict regulatory requirements for cleanliness and accuracy in the pharmaceutical and food and beverage sectors, as well as handle delicate cosmetic formulations with care.

How Do Modular Designs Enable Scalability and Support Different Production Volumes?

Modular design flexibility is centered on the ability to add or remove components as needed. For scalable production, you can add more filling nozzles to increase speed or integrate new stations for capping and labeling. This allows your line to handle both small test batches and high-volume runs, adapting perfectly to your business needs.

Can Modular Filling Systems Reduce Product Waste and the Risk of Human Error?

Yes. Automation and precision controls ensure error-free filling by dispensing the exact amount of liquid every time. This accuracy virtually eliminates overfills and spills, leading to significantly reduced waste. By automating the process, you also remove the variability and potential for mistakes associated with manual labor, saving both product and money.

What Types of Filling Machines and Mechanisms Can Be Integrated into a Modular System?

Integrated filling machines can incorporate a wide range of filling mechanisms to suit different liquid types. Common options include:

- Piston Fillers: Ideal for thick, viscous products like pastes and creams.

- Gravity Fillers: Best for thin, free-flowing liquids.

- Peristaltic Pump Fillers: Perfect for sterile or high-purity applications, as the product only touches the tubing.

- Overflow Fillers: Ensure a consistent cosmetic fill level across all containers.

How Do Modular Filling Systems Handle Different Container Sizes and Shapes?

These systems offer exceptional container flexibility thanks to adjustable guide rails, interchangeable star wheels, and easily swapped nozzle heads. Operators can quickly reconfigure the line for different bottle heights, widths, and shapes with minimal tools or downtime. This allows a single line to handle a diverse range of packaging formats efficiently.

What Are the Advantages of Using Modular Filling Systems Compared to Traditional Machines?

When comparing modular vs. traditional filling, modular systems have a clear edge. They offer superior flexibility to adapt to new products, are more cost-effective to scale, and experience significantly higher uptime due to easier maintenance. Traditional monolithic machines are rigid and quickly become obsolete, whereas modular designs evolve with your business needs.

How Do Modular Filling Systems Ensure Hygiene, Safety, and Compliance?

These systems are built to meet strict hygiene standards and ensure safety compliance. They are typically constructed from food-grade stainless steel, designed for easy cleaning and sterilization, and feature enclosed designs to prevent contamination. Integrated sensors monitor the process to maintain quality, helping businesses meet and exceed regulatory requirements.

Conclusion

Modular filling systems offer a powerful combination of flexibility, efficiency, and scalability that traditional machinery cannot match. By embracing automation and a modular design, businesses can reduce costs, improve product quality, and future-proof their operations. This adaptable technology is a strategic investment for any manufacturer looking to thrive in a competitive market.

Ready to see how a modular approach can transform your production line? Contact us to learn more about our customized modular filling solutions.