Efficiency and precision are of great importance in the fast-changing world of drink manufacturing. The filling of beverages is a critical step in guaranteeing that goods are filled correctly thus preserving quality and increasing the output as well. This write-up is going to discuss different categories of beverage fillers, their technological advancements, and their effect on the production process. We shall also look at how these machines can change operations, cut down on wastage, and improve product safety, thereby giving manufacturers an upper hand in the market. Whether you operate a small-scale craft brewery or a large commercial plant, it is important that you know what modern filling solutions can do for your production line in terms of capabilities and advantages.

Table of Contents

ToggleHow Do Beverage Filling Machines Work?

Understanding the Basics of Filling Machines

A systematic process is used in the operation of beverage filling machines, which consists of several main parts. It serves to distribute a specific amount of liquid into packages through different methods, including gravity, pressure, or vacuum, among others. These are:

- Filling Nozzles: They make sure that the liquid is evenly placed inside containers while being able to adapt for various bottle sizes.

- Container Handling Systems: Conveyors and guides place the containers right under the filling nozzles so as to maintain their position.

- Flow Meters: These are employed in measuring what volume of liquid is being discharged; thus ensuring uniformity and compliance with set levels.

- Control Systems: Machine operations are controlled by programmable logic controllers (PLCs) that facilitate instant modifications as well as monitoring of fill processes in real time.

All these components collaborate towards the attainment of accuracy and efficiency at higher rates, which are necessary for product quality control systems and regulatory compliance purposes.

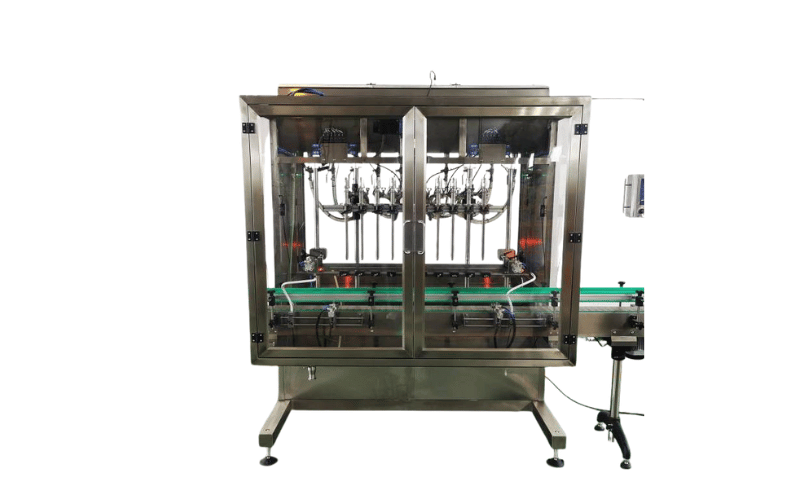

Components of a Beverage Filling Machine

To ensure that beverage-filling machines work well and perform their tasks quickly, they have several important parts. These are:

- Filling system: It is the part of a machine that uses gravity or vacuum systems to deliver drinks accurately into containers.

- Capping unit: This component seals filled bottles tightly so as to keep the product fresh always, it can be automated for faster production.

- Labeling system: It is necessary for branding purposes and conformity with legal requirements; therefore, this element must apply labels uniformly onto all filled bottles.

- Control panel: Operators can check fill levels, speed up or slow down operations among other settings using this interface that also displays operational statuses.

- Sanitation systems: Since there should never be any cross-contamination in food processing industries, sanitation systems integrated within these devices clean them automatically after use before another batch starts.

Every single one of these components helps make the process of filling efficient, reliable and meet industry demands for manufacturers to maintain product quality integrity.

Types of Beverage Filling Machines

Based on their operation and use, beverage filling machines can be divided into several types. Here are the most common:

- Gravity Fillers: These machines utilize gravity for liquids such as wine or water which are free-flowing. Although they work at slower speeds, gravity fillers are simple and cheap.

- Pressure Fillers: Pressurised systems are used by these devices to fill thicker fluids quickly like juice drinks and carbonated beverages. It prevents over-foaming while ensuring that the container gets filled.

- Vacuum Fillers: Vacuum conditions enable this type of equipment to fill frothy products or those which need controlled environment during filling e.g., dairy goods with easy foaming properties. The main purpose is to limit air exposure between product content.

- Timing Fillers: Time intervals form the basis for this category of fillers, where each container receives liquid amounts in precise quantities based on timed durations; it is very useful in high-speed bottling lines.

- Rotary Fillers: Designed for massive production capacities, rotary fillers allow continuous running speed due to their ability to handle large numbers per unit of time. They have a station where containers rotate around during filling.

All filling machines have been designed around particular manufacturing requirements together with product features so that companies can maximize efficiency levels without compromising on quality throughout the process.

What Are the Advantages of Automatic Filling Machines?

Efficiency and Speed in the Filling Process

Automatic filling machines greatly bolster the efficiency and speed of the process by cutting down on manual labor and simplifying processes. Such devices are built to perform fast-filling rounds, which facilitate higher amounts of output than hand-based techniques do. Accuracy in automated systems reduces product loss and guarantees uniformity in filling levels, a necessary requirement for quality control. Apart from this, more advanced sensors alongside their corresponding control units allow for continuous tracking as well as prompt corrections, thus maximizing productivity while minimizing downtimes during operation. In conclusion, when integrated into production systems, automatic fillers enhance productivity throughout manufacturing plants.

Consistency and Accuracy in Fill Volume

To maintain product quality and meet industry standards, it is important to have a consistent and accurate fill volume. This task is performed by automatic filling machines. Such machines are fitted with load cells and flow meters among other technologies that utilize the most current advancements in technology. Their main role is to ensure that each package receives the exact quantities of contents, thereby reducing variations that are common with manual methods of filling. The precision achieved by these gadgets helps prevent underfilling or overfilling and also follows guidelines related to the packaging and labeling of products. Manufacturers can ensure uniformity in output throughout different production batches if they automate measurement for fill volumes; this will earn them consumer confidence, as well as enhance brand image since people like things that look alike.

Minimizing Waste and Maximizing Output

In present-day production environments, it is important to minimize waste while maximizing output, and this can be achieved through the use of automated filling machines. Such systems have the ability to detect inefficiency by continuously monitoring and analyzing data in real-time; thus, they are able to correct themselves where necessary. An example is when they employ predictive maintenance methods that help operators anticipate possible breakdowns, thereby minimizing production halts.

Furthermore, automatic fillers connected with stock management systems enhance raw materials control which leads to less wastage. This software keeps records of usage trends so manufacturers can optimize their supply chains and cut down on excess inventories. Also, machine learning advances coupled with artificial intelligence are making filling processes more adaptive to changing production needs through dynamic response, increasing output while using minimum resources. Doing so, not only does it improve efficiency but also complies with the sustainability drive as it reduces manufacturing effects on the environment.

How Do Beverage Filling Machines Enhance Production Lines?

Streamlining the Production Process

Beverage-filling machines improve production lines by filling automatically, thus increasing speed and precision. They can also be synchronized with other machines to save time and eliminate mistakes that may arise from human handling. Quality control is achieved through precise engineering, which guarantees that all containers are filled with equal amounts of liquid. Additionally, integration into conveyor systems enables an uninterrupted flow of products, while real-time analytics offer data-driven thinking necessary for fast decision-making and operational tweaks. This holistic method results in better efficiency coupled with reduced labor charges, leading to increased output during the making process.

Integration with Existing Production Systems

The incorporation of beverage-filling machines into current production systems is important if one wants to establish a smooth manufacturing workflow. By making use of common communication protocols like OPC UA or MQTT, these machines are able to connect well with other hardware and software platforms through which data can be shared uniformly and activities coordinated accordingly. This will, in turn, allow for monitoring fill levels and production speeds on a real-time basis, among other key measures that can be adjusted promptly for continued peak performance. Additionally, by embracing Industry 4.0 concepts, manufacturers can utilize IoT devices to collect and analyze data along the assembly line, thus improving predictive maintenance while reducing downtime. Basically, what this means is that proper integration enhances not only operational efficiency but also responsiveness in meeting changing market needs at different stages of the product lifecycle.

Scalability and Flexibility in Production Rates

Modern drink production relies heavily on scalability and flexibility. These two elements allow the industry to adapt itself according to changing market needs as well as production requirements. Producers can scale their capabilities up or down with seasonal trends and consumer shifts by using modular filling systems. In addition, they may also reconfigure automated systems for different products, which greatly reduces operational disruptions through decreased changeover times. These, among other advanced manufacturing technologies like robotics or AI-driven analytics, enable real-time adjustments in production rates so that output matches demand without sacrificing quality. Ultimately, this strategic focus on scalability enhances investment efficiency while keeping pace with market dynamics proactively rather than reactively.

Which Technologies Are Used in Beverage Filling Machines?

Advances in Automated Filling Technology

Beverage production has become much more precise and efficient with the recent developments in automated filling technology. Among these advancements are fast servo-driven fillers that are accurate when it comes to volume control and also limit spillages. Another development is the use of vision systems, which carry out quality checks in real time and make sure fills meet strict regulatory requirements. Most automation software now has machine learning algorithms, which, through studying past information, improve predictions on different production environments, thus increasing their precision levels. With such technological improvements, producers can handle larger quantities within the same period while still upholding strict quality standards.

Filling Nozzles and Precision Filling

In the precision filling of drinks, fill nozzles are very important since they directly affect the precision of fills as well as overall efficiency in production. Current fill nozzles have adjustable heights and flow rates, among other features that make it possible to tailor them according to the nature of the beverage under processing. Additionally, anti-drip designs integrated into these nozzles help reduce spillage, thus cutting on wastage while improving product yield. Magnetic and ultrasonic sensors are some of the precision filling technologies used today; they give instant feedback on levels filled so that adjustments can be made in real-time. Such inventions ensure that filling always meets production targets and quality requirements, hence enhancing operational excellence within the beverage manufacturing sector as a whole.

Innovations in High-Quality Filling Solutions

Presently, what distinguishes high-quality filling solutions is automation, sensor technology improvement, and Industry 4.0 integration. The use of artificial intelligence-enabled smart filling systems for accuracy and flexibility on different product lines among major manufacturers. Some systems can use computer vision technology to observe fill levels in real-time thereby making instant corrections necessary to ensure precision as well as meet quality standards.

Furthermore, there has been an increase in the adoption of environmentally friendly materials with filling equipment, thus reflecting global tendencies towards sustainable manufacturing. Modern filling machines are designed such that they consume less power but still work faster and reliably. Again, this also allows them to connect through IoT; hence, they can easily be integrated into existing supply chain systems, which in turn enables predictive maintenance, leading to reduced downtime. These improvements jointly create a more sensitive and productive production atmosphere where there is uniformity in terms of better products since time is saved, too.

What Considerations Should Be Made When Choosing a Beverage Filling Machine?

Evaluating Production Needs and Consumer Demand

When choosing a drink-filling machine, ensure that you evaluate your specific production volume needs vis-à-vis the potential of the machinery to meet those requirements without causing unnecessary downtimes. The decision on which filling technology to use should be guided by an understanding of who your target market is and what they prefer as far as beverages are concerned; this will also determine what kind of drinks one may want to produce. There are many factors that need consideration when selecting a suitable device, such as product thicknesses (viscosities), sizes or shapes of packages, among others, which could affect compatibility with materials used for making them, and so on. Additionally, it would be wise to consider seasonal fluctuations in demand when deciding between fixed capacity and flexible machines since the latter can adjust themselves according to different production situations depending on need. Finally, it is important in every business setting, especially where there are competitors involved, like the beverage industry, to always align consumer needs with the company’s abilities, thus gaining the upper hand over rivals.

Choosing the Right Machine for Different Bottle Sizes and Types

When choosing a drink-filling machine, it is necessary to determine the range of bottle sizes and types that will be used in manufacturing. Machines must be able to adjust for different heights and diameters which means they should be suitable for both small glass bottles as well as large plastic ones. Moreover, the choice between gravity, volumetric or pressure filling methods has to be made based on specific needs posed by materials and design of bottles. For example, fragile containers may need gentle treatment while being transported so as not to break them, while solid plastics could withstand faster rates of filling. That’s why evaluating how well packaging formats match with a given filler not only makes production easier but also increases operational efficiency during this stage and lowers mistake risk.

Cost and Maintenance of Filling Machines

The cost of beverage-filling machines can widely vary depending on the kind of machine, its capacity, and the level of automation. For a few thousand dollars, one may acquire entry-level machinery, while a high-speed, fully automated system can cost between tens to hundreds of thousands or even more than one million dollars. It is important also to take into account continuous maintenance costs, which involve regular inspections and replacement of parts, among others. Routine checkups not only increase the life span for such equipment but also ensure that they work at all times with equal effectiveness. Some good practices include creating a timetable for servicing them frequently, training workers on how to operate them correctly, and fixing any operational malfunctions promptly so as to minimize downtimes. In addition, there are manufacturers who offer contracts for maintaining their products; these contracts usually provide regular services and technical support, thus making it possible for one to manage his line cheaply while keeping it at peak performance levels during production runs.

Reference Sources

Frequently Asked Questions (FAQs)

Q: Can you explain what beverage-filling machines are?

A: What do we mean by beverage-filling machines? These are packaging machines that fill bottles or containers with different types of liquids ranging from water, juice, soda to other drinks. These devices such as these make sure that every pack is filled with precision and uniformity thus enhancing efficiency in the packaging industry.

Q: How does a bottle-filling machine work?

A: How does a bottle-filling machine operate? It puts bottles in place automatically, dispenses liquid into them, and seals the containers. Filling heads equipped on these machines ensure accuracy while filling each bottle with product at consistent levels.

Q: What kind of advantages should I expect when using automatic fillers?

A: When it comes down to benefits of automated fillers they include but not limited to higher production speed, lower labor costs incurred as well as better accuracy and consistency in filling things up. The packaging process for beverages has never been same again since this equipment was introduced into their system.

Q: In what ways do liquid fillers revolutionize production?

A: Liquid filers have revolutionized production by being fast enough for use in high-speed filling systems, hence enabling efficient operation during manufacturing processes where time is highly valued; also, they eliminate the need for manual labor, which may be tedious or boring thereby ensuring that all containers get filled properly thus improving productivity levels throughout an organization without compromising on quality standards set forth by regulatory bodies.

Q: Are there different types of liquid fillers available today?

A: Yes, there are many types of liquid fillers. These may include piston filler, gravity filler or vacuum type machines each suitable depending on viscosity levels among other properties exhibited by various fluids during different stages within their manufacture process so one needs to select an appropriate device which matches specific requirements concerning this matter according to particular situation encountered at hand.

Q: What can beverage filling machines be filled with?

A: A wide range of liquids, such as water, carbonated drinks, juices, alcoholic beverages, and dairy products, can be filled using beverage filling machines. They help to fill low and high-consistency viscosity liquids efficiently.

Q: How do I increase the efficiency of my production by using an automated filling machine?

A: Automated filling machines speed up the rate at which bottles are filled thereby improving efficiency. This leads to consistency in the quantity of liquid poured into each bottle hence standardized production output for those that require high supply.

Q: What factors should I consider when choosing a liquid filler?

A: The liquid being filled; required fill volume; production speed; and level of automation required are some of the things to consider when selecting a liquid filing machine. It is essential to choose a machine with necessary features that will meet your production objectives.

Q: Are there many containers of different shapes and sizes available for filling machines?

A: Yes, most modern filling machines are versatile, hence they have been designed to accommodate various container sizes and shapes. The adjustable settings often come in handy whenever there is need for altering the dimensions of the container hence it could be used in diverse production contexts.

Q: How does hygiene and product safety get ensured by filling equipment?

A: These include sanitary design, easy-to-clean components as well as materials meeting food industry regulations amongst other measures instituted on filling machinery as ways through which these needs have been achieved by this equipment. Thus, maintenance schedule should include proper cleanup plans since hygiene is a prerequisite.